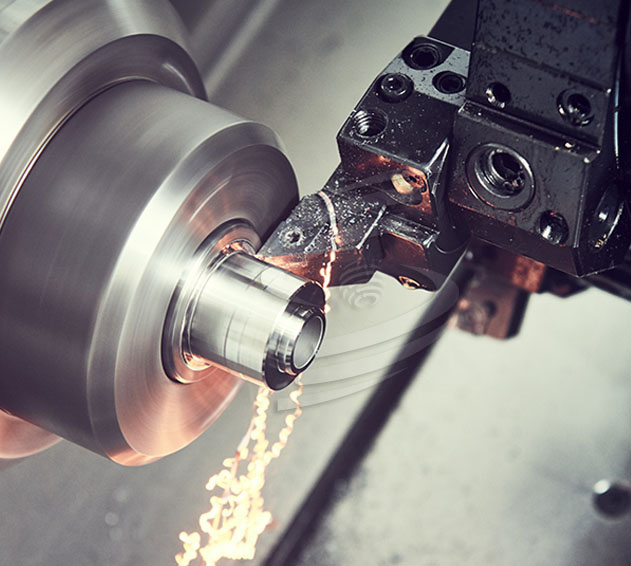

We have established a state of art infrastructure with latest automated machineries which is segmented into different divisions for smooth and hassle free working. With over 20,000 sq. ft. manufacturing area, segmented for each area of operation, each segment has necessary facilities including modern machineries and tools. Our infrastructure has not only enabled smooth production of large batch but also helped us to make our position strong in global market.

Our flexible assembly system, packaging and immediate shipping allows us to meet any important requirement including custom labeling, Bar coding and customized solution for packaging. For our precise clients we offer export worthy customized packaging for the shipment of sea or air cargo. Our packing department ensures that products are delivered within stipulated time frame to the each client as per their custom requirement.

Copper & Copper Base Alloys, Aluminium,

Mild Steel & Stainless Steel

Ferrous & Non-Ferrous Material

Size Up to 15kg

Forging Part

Size Up to 25kg

Casted Parts

Up To ø500 MM

Up to 1000 MM

Natural, Buffed, Blasted

Nickel, Tin, Silver, Chrome,

Anodizing Gold & Red, Zn-ni, Anti-rust Coating,

Galvanizing, Annealing, Hardening Electroless Platting Treatment etc.

ISO 9001-2015, PPAP-level4, RoHs, Reach Compliances, PDIR, M.T.C

Other Documents as per Customer's Requirments

As Per Customer's Requirement

Production Machines |

|||

Type of Machine |

Machining Range |

||

| CNC Linear | 5.00 mm to 50.00 mm (Length : 120.00 mm) | ||

| CNC Turret | 5.00 mm to 110.00 mm (Length : 250.00 mm) 5.00 mm to 150.00 mm (Length : 250.00 mm) |

||

| VMC | 200.00 mm X 200.00 X 300.00 mm | ||

| Cam OperatedAutomatic Machine | 1.00 mm to 8.00 mm | ||

| Cam Operated Single Spindle Machine | 20.00 mm to 32.00 mm Round 15.00 mm to 25.00 mm Round 11.50 mm to 19.00 mm Round |

||

| Milling Machine | 2.00 to 20.00 mm 5.00 to 40.00 mm |

||

| Cutting Machine | 1.00 mm to 40 mm Round 20 mm to 200 mm Round |

||

| Press | 2.00 to 15.00 mm Depth :

20.00 mm 15.00 mm To 50.00 mm Depth : 30.00 mm 0.100 to 1.000 kgs Forging Marking Depth 0.10 To 0.70 mm |

||

| Hot Air Oven | 450 °C Max | ||

| Shot Blasting | 70.00 mm X 70.00 X 300.00 mm (Length : 400.00 mm) | ||